Writer: Eric Bearing Limited

Bearings are essential components in gearboxes, enabling smooth rotation, reducing friction, and supporting axial and radial loads. Their proper selection and installation significantly impact gearbox performance, efficiency, and lifespan. This article explores the types of bearings used in gearboxes, their functions, and key considerations for optimal operation.

Types of SKF Bearings Used in Gearboxes

Different bearing types are selected based on load capacity, speed, and alignment requirements:

SKF Deep Groove Ball Bearings

Commonly used in high-speed gearboxes due to low friction.

Suitable for moderate radial and axial loads.

Example: Small automotive transmissions.

SKF Tapered Roller Bearings

Handle combined radial and axial loads efficiently.

Often used in heavy-duty gearboxes (e.g., truck transmissions).

Allow precise axial positioning of gears.

Cylindrical Roller Bearings

Optimized for high radial loads.

Used in industrial gearboxes where heavy radial forces dominate.

Provide high rigidity and durability.

Spherical Roller Bearings

Accommodate misalignment and heavy loads.

Common in large industrial gearboxes subject to shaft deflection.

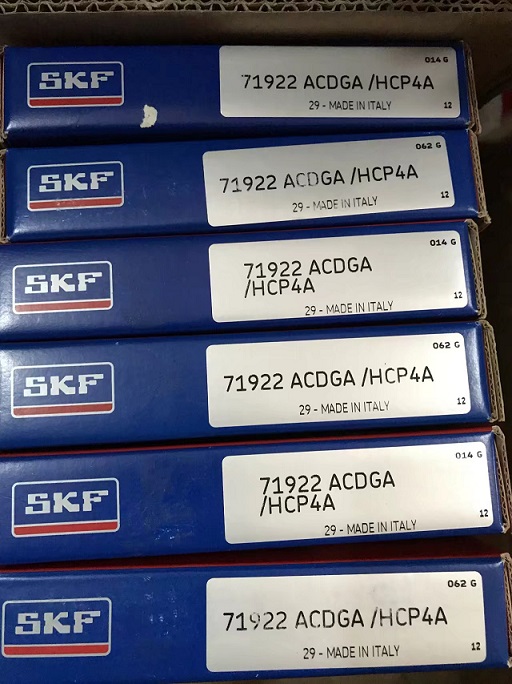

SKF Angular Contact Ball Bearings

Support high axial and radial loads in high-speed applications.

Used in precision gearboxes (e.g., wind turbine gearboxes).

Key Functions of Bearings in Gearboxes

Load Support: Bearings absorb forces from gears, shafts, and external loads.

Reduction of Friction: Minimize energy loss and heat generation.

Alignment Maintenance: Ensure proper gear meshing and shaft positioning.

Vibration and Noise Damping: Improve smooth operation and reduce wear.

SKF Bearings play a crucial role in gearbox performance, affecting efficiency, durability, and noise levels. The right bearing selection—based on load, speed, and environmental conditions—ensures reliable operation and reduces maintenance costs. Advances in bearing materials (e.g., ceramic hybrids) and lubrication technologies continue to enhance gearbox performance in demanding applications.

Tel: 00852-30697500

Fax: 00852-30697511

Email: sales@ericbearing.com

Message: Click Here Message!